Lab-grown diamonds. They are captivating the jewellery world, offering a compelling alternative to mined diamonds. But how exactly are these marvels of science created? It’s not magic, but it certainly feels like it! The secret lies in two primary technologies: CVD (Chemical Vapor Deposition) and HPHT (High Pressure/High Temperature). These are the “magic wands” of modern gem creation, and understanding them unlocks a deeper appreciation for the brilliance and innovation behind lab-grown diamonds.

Let’s dive into the science and explore how these incredible processes work, and how the top lab-grown diamond growers are pushing their boundaries:

CVD (Chemical Vapor Deposition)

Imagine building a diamond atom by atom, layer by layer. That’s essentially what Chemical Vapor Deposition (CVD) achieves. Think of it like a high-tech “diamond printing” process.

- The Concept: CVD starts with a tiny diamond seed crystal. This seed is placed inside a vacuum chamber filled with carbon-rich gases, like methane, along with hydrogen and other gases. Energy, often in the form of microwaves, heats the gases into a plasma state. This plasma is like a superheated, energized gas where the molecules are broken down.

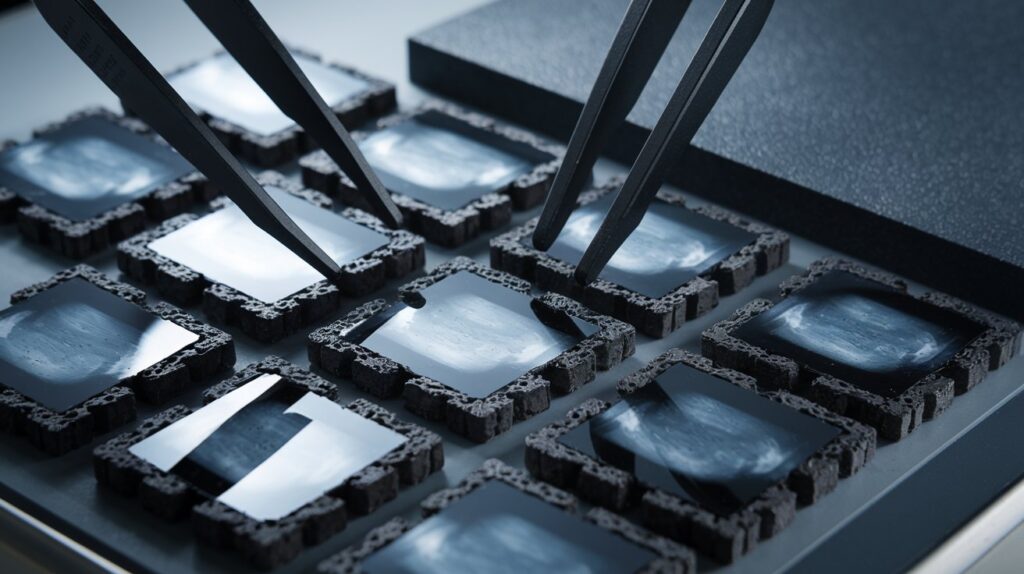

- The Process – Atom by Atom Growth: In the plasma, carbon atoms are released and gently rain down onto the diamond seed crystal. These carbon atoms, under precise temperature and controlled conditions, slowly deposit and crystallize onto the seed, expanding its crystal structure, layer by layer, upwards and outwards. It’s a meticulously controlled process that allows for the creation of large, high-quality diamonds.

- Key Advantages of CVD:

- Large Size Potential: CVD is particularly well-suited for growing larger diamonds, including those suitable for significant centre stones in jewellery.

- High Clarity & Colorless Diamonds: CVD excels at producing Type IIa diamonds, which are exceptionally pure and often colorless, highly prized in the gem world.

- Cost-Effective Scaling (Relatively): While still technologically advanced, CVD can be more energy-efficient and cost-effective for large-scale production compared to HPHT in some aspects.

- Leading Companies Innovating with CVD:

- WD Lab Grown Diamonds: Masters of CVD, consistently pushing the limits of CVD technology for larger, higher-clarity stones. Their expertise is foundational to the CVD diamond industry.

- Diamond Foundry: Leveraging proprietary plasma reactor technology to achieve rapid and sustainable CVD diamond growth at scale, with a strong focus on efficiency and environmental responsibility.

- Greenlab Diamonds: Indian grower aggressively expanding CVD production in India, utilizing CVD’s scalability to become a major global supplier.

- ALTR Created Diamonds: Focusing on CVD for consistent quality and production for their fashion-forward jewelry brand, capitalizing on CVD’s ability to create desirable colorless stones.

- Carnegie Institution for Science: While not commercial growers, their research breakthroughs at Carnegie on CVD were fundamental and continue to influence CVD innovation across the industry.

HPHT (High Pressure/High Temperature)

HPHT, or High Pressure/High Temperature, takes a different approach: it mimics the natural conditions deep within the Earth where diamonds form over billions of years. It’s like recreating the Earth’s mantle in a controlled laboratory setting.

- The Concept: HPHT utilizes a growth cell containing carbon material, often dissolved in a metallic solvent catalyst. This cell is subjected to immense pressure (around 1.5 million pounds per square inch) and extremely high temperatures (around 1500 degrees Celsius – similar to molten lava!).

- The Process – Pressure and Heat Driven Crystallization: Under these extreme conditions, the carbon material dissolves in the metallic solvent. Then, a temperature gradient is carefully controlled within the growth cell. In the cooler part of the cell, carbon becomes supersaturated and crystallizes out, growing on diamond seeds placed in that cooler zone. This process essentially replicates the way diamonds form naturally over geological timescales, but accelerates it dramatically.

- Key Advantages of HPHT:

- Fancy Color Creation: HPHT is particularly effective at producing certain fancy colored diamonds, especially vivid yellows and pinks. By introducing specific trace elements during growth, growers can control the color outcome.

- Potentially Robust Growth (for certain diamond types): HPHT can sometimes be advantageous for growing certain types of diamonds or achieving specific internal characteristics.

- Leading Companies Innovating with HPHT:

- IIa Technologies: HPHT specialists, focused on growing larger, high-carat diamonds using HPHT methods. Pushing the size limits for HPHT-grown gems.

- Chatham Created Gems (Gemesis legacy): Pioneers in HPHT fancy colored diamonds, particularly known for vibrant yellows and pinks, continuing to innovate within HPHT color synthesis.

- New Diamond Technology (NDT): Russian company excelling in both CVD and HPHT, but with significant advancements in HPHT for large, high-quality, and fancy colored diamonds, pushing HPHT technology to new levels for premium gem production.

CVD vs. HPHT: A Quick Comparison

| Feature | CVD (Chemical Vapor Deposition) | HPHT (High Pressure/High Temperature) |

| Growth Environment | Vacuum chamber, carbon-rich gas plasma | High-pressure, high-temperature cell |

| Diamond Type Strengths | Large, colorless to near-colorless, Type IIa | Fancy Colors (esp. yellow, pink), potentially robust growth |

| Cost (Generally) | Can be more energy-efficient for scaling | Can be more energy-intensive |

| Key Players | WD Lab Grown Diamonds, Diamond Foundry, Greenlab, ALTR, (Research: Carnegie Inst.) | IIa Technologies, Chatham (Gemesis), NDT |

The Future is Bright and Brilliantly Grown

Both CVD and HPHT are remarkable feats of modern science and engineering. They represent two distinct pathways to creating diamonds that are, in every essential way, identical to their mined counterparts. And the innovation doesn’t stop here. Companies are constantly refining these technologies, striving for:

- Larger Diamond Sizes: Pushing the boundaries of how large lab-grown diamonds can be consistently grown, especially in gem-quality.

- Faster Growth Rates: Reducing the growth time to make production more efficient and cost-effective.

- New Fancy Colors & Enhanced Properties: Exploring ways to create an even wider spectrum of fancy colors and potentially tailor other diamond properties through growth control.

- Lower Energy Consumption & Sustainability: Continuously improving the energy efficiency and environmental footprint of both CVD and HPHT processes.

The story of lab-grown diamonds is a story of scientific ingenuity, environmental consciousness, and a revolution in the world of luxury. CVD and HPHT are the technologies at the heart of this transformation, and the companies utilizing and innovating upon them are truly crafting the future of diamonds, one atom – or one press of immense pressure – at a time.